Valves and other process mechanical isolation’s (such as pig trap doors and vessel manways) have an important, safety-critical function in many industrial processes. The accidental, inadvertent operation of important valves in a process system can lead to serious consequences.

Failures or operational errors during procedures that do not occur frequently (i.e. pigging operations, tank line up, and isolation & reinstatement of process plant) are one of the main causes of loss-of-containment incidents, and in extreme cases may lead to major accidents.

For any Pipeline Operator, the primary focus is on minimising the risk of injury/harm to people and the environment, particularly where process operations have the potential to create a major accident hazard. Preventing loss of containment also improves environmental protection and compliance, can reduce business interruption.

The greater the potential hazard, the more effective, secure and controlled the isolation philosophy needs to be. Engineered solutions and good design maximise inherent safety and are fundamental to achieving safe and effective plant isolation. These Engineered design solutions are preferred to the reliance on procedural controls (such as operating procedures, risk assessments, permits and toolbox talks), or the use of personal protective equipment to compensate for the risks associated inadvertent valve misalignment.

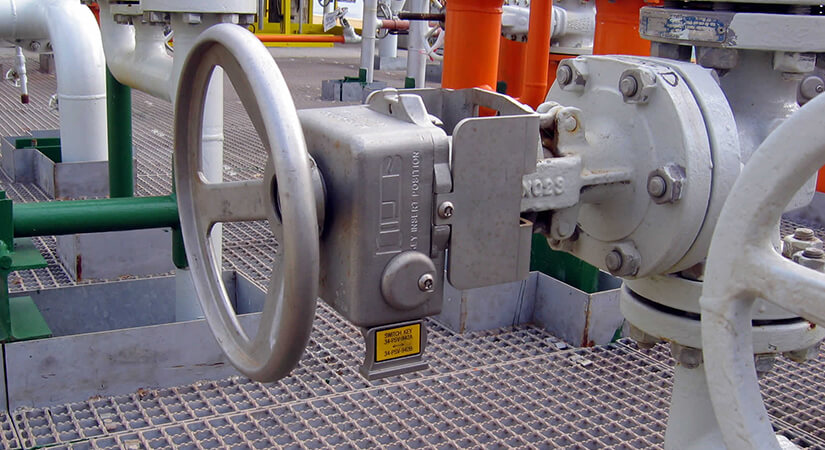

One engineered design solution to which provide can add significant safety insurance to a process isolation philosophy, is the installation of mechanical valve interlocks to safety, and operationally critical valves.

Essentially mechanical valve interlocks are used wherever a single or sequence of mechanical isolation operations and adherence to procedure is required to safeguard personnel, plant or the environment.

Valve interlocks are used for a wide variety of applications across the Oil & Gas, Nuclear and Water industries, within chemical plants and refineries both on and offshore, some of which are listed below

- pig launching and receiving

- tank line ups

- filter change outs

- line sampling

- vessel access into equipment for inspection and/or maintenance

- process system start-up & shut down

- train alignment

- pump routing

- pressure relief lines (PRVs)

Mechanical valve interlocks provide the most effective benefits in applications where breaking containment is necessary as part of the work scope.

Valve interlocks suit all types of lever and hand wheel manually operated valves (including ball, butterfly, plug, gate and globe valves), gear operated valves, motorised valves, and pneumatically operated valves. Interlocks can be installed to suit both top and side mounted stems i.e. vertical and horizontal operation. Available in single-key or double-key versions, locking the valve in either an open or closed position.